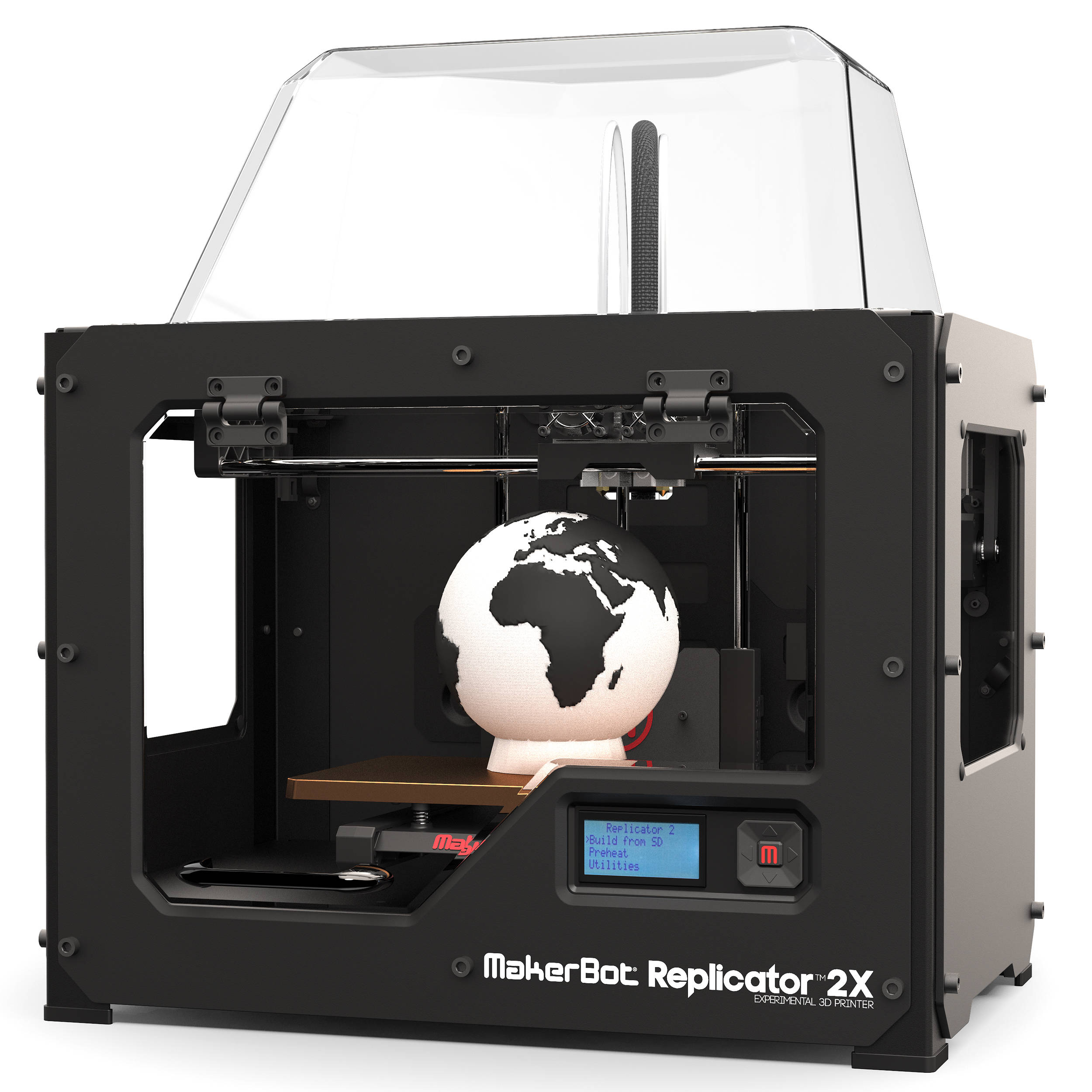

MakerBot Replicator 2 and 2X Desktop 3D Printers

The MakerBot Replicator 2 and 2X Desktop 3D Printers started a dramatic shift in user experience an accessibility of 3D printing technology. By utilizing low cost and widely used motion control strategies along with safe inexpensive printing materials, it became possible to bring effective rapid prototyping technology to the masses.

Continuous Product Improvement

Product engineering rarely ends with the start of production, and this remained true with the Replicator 2 and 2X. During my time with MakerBot the primary factory was located in Brooklyn, NY, allowing for seamless coordination of quality and feature changes.

My first projects at MakerBot as an electrical engineer involved resolving regulatory compliance and thermal control issues with the Replicator 2X. I coordinated directly with suppliers and our manufacturing side to implement product changes while minimizing scrap and downtime.

Responsibilities

Electronics Design and Development

CM / Supplier Coordination and Management

Quality / Manufacturing Engineering

Safety / Wireless Regulatory Compliance

Competitive Intelligence Analysis

Project Management